Mythri Metallazing India carries thermal spray zinc coating also called as metallizing/thermal spray galvanizing a pure 99.9% of zinc will be thermally sprayed on the surface of steel as per IS5905 to the recommended coating thickness which can stop the corrosion on iron and steel surfaces for long time this process is very widley used steel fabricated materials and fertiliser/petrochemical/steelplants and many more

Risk Free:

There is zero risk of heat distortion or weld damage of the surface.

No Limitation:

The spray galvanizing media can support surfaces of any shape and volume.

Economical Process:

The spray galvanizing process is highly cost effective and economical.

Flexible Control:

The properties of the thermal spray coating can be controlled.

Durable Structure:

The coating can act as a base and offer long life structures.

Catholic Protection:

The zinc Application forms a protective layer against corrosion.

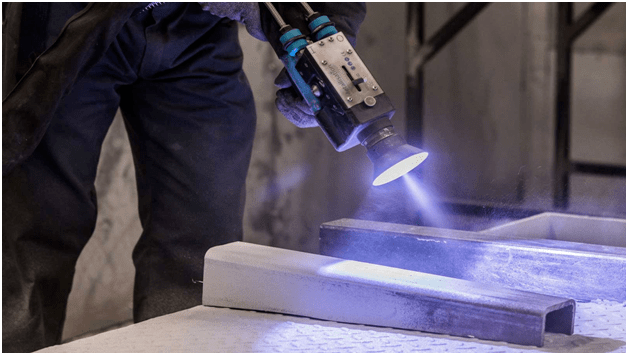

Blast Cleaning:

The surface of the metal is prepared by abrasive blasting with thorough cleaning and roughening.

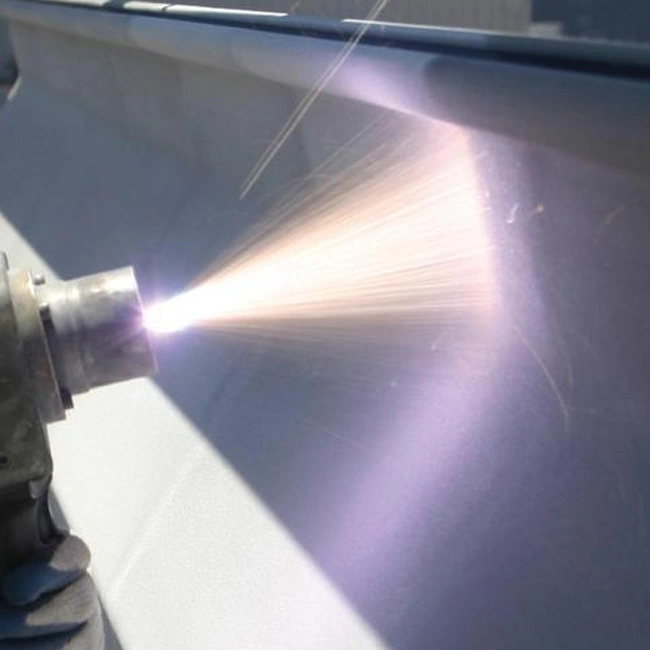

Arc Spraying:

Zinc wire at a controlled rate is applied into an arc spraying process and the atomised metal impinges the coated surface.

Galvanizing:

Zinc deposited follows a process through spraying in contrast to the conventional methods of galvanizing.

Test for Thickness

At Mythri, ensuring that the coating meets the accepted national and international standards. A self calibrated coating thickness gauge with samples are tested for thickness of Zinc as per IS:3202:1982.

Test for Bond

At Mythri, Mechanical bonding of zinc coating to the substrate is tested using an imported bond tester as per ASTM-D 4541-1985. A dolly is fixed on the sample using adhesives to indicate the bonding strength in PSI

Test for Precision

At Mythri, the sample is subjected to multiple levels of dipping in copper sulphate Solution ideally 4 times for a duration of one minute each and checked for coloration indicating non uniform coating at the 4th level.

Test for Purity

At Mythri, the purity of zinc is tested at an external lab ensuring 99.95% as per the IS:209 standards along with the certification. The purity test certificates of zinc are available to the clients on demand.

Mythri supports maximisation of timely deliverables to real-time schemas with well planned and executed solutions without conventional lags.