Our promise to keep delivering the best solutions with consistent value addition to our clients

Our business processes ensure seamless execution with increased efficiency at minimal costs

Our company’s value systems always meets with technological standards with clear functionality of business

Our priority relies on the safety of every business activity that we take up creating a sustainable environment

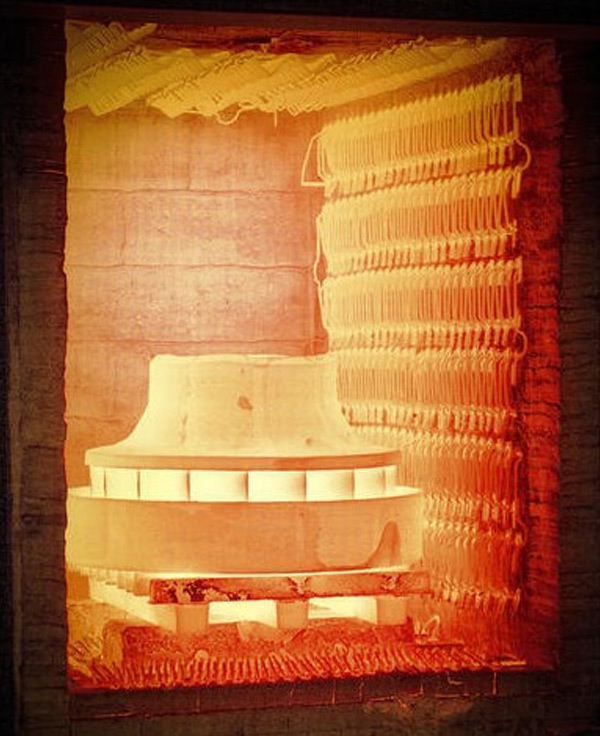

Mythri Metallizing India stands as a firsthand identity among the industry. With an absolute intention of building quality relationships and offering end-to-end anti-corrosion solutions Mythri Metallizing India believes in efficiency and time bound processes are the key to high quality and cost-effective solutions.

20+

Years Experience

1000+

Industries Served

300+

Projects Completed

A decade old expertise in surface finishing and spray metallizing Mythri, today stands strong forging strategic relationships with its stakeholders. Join us on the journey.

CONNECT

Skilled engineering, technical professionals, continuous R&D, scalable workforce. A one stop solution to surface finishing & anti-corrosion solutions.